In today's world of increasingly impressive and compact electronics, successful thermal administration is no more a luxurious – it's a requirement. Overheating may lead to lowered general performance, procedure instability, as well as catastrophic failure. which is the place custom made heat sinks are available in. as opposed to off-the-shelf remedies, custom made designs are customized to the precise wants within your application, ensuring best heat dissipation and reliable operation. This information will take a look at the crucial position of tailor made heat sinks, notably Extruded Profiles Heatsink, in different industries and supply insights into developing and balancing Price tag with functionality.

Table of contents:

crucial Industries That Benefit from tailor made Heat Sink methods

the best way to design and style a custom made Heat Sink for Optimal Thermal Management

Cost vs. general performance: Balancing Custom Heat Sink technical specs

vital Industries That Benefit from customized warmth Sink options

quite a few industries trust in tailor made warmth sinks to take care of the efficiency and longevity in their Digital components. The telecommunications sector, with its dense networking devices, Added benefits significantly from customized thermal options that avert overheating and assure uninterrupted assistance. equally, the power electronics marketplace, handling high-voltage and high-recent apps, necessitates robust warmth sinks to manage the extreme warmth produced by ability transistors and rectifiers. Additionally, the aerospace and protection industries, where dependability below Serious situations is paramount, depend on personalized designs to resist harsh environments and retain significant program features. Even in health care machines, the place precision and protection are essential, custom made warmth sinks Perform a significant function in avoiding overheating and making sure correct diagnoses and therapies.

tips on how to Design a Custom warmth Sink for exceptional Thermal administration

building a good personalized warmth sink entails watchful consideration of many elements. First, being familiar with the heat source and its thermal qualities is crucial. This incorporates identifying the power dissipation, temperature limitations, and mounting needs. up coming, selecting the ideal materials is vital. Aluminum is a well-liked option on account of its fantastic thermal conductivity, light-weight, and value-success, creating Extruded Profiles Heatsink a typical Alternative. Copper offers top-quality thermal performance but is heavier and more expensive. The geometry of the heat sink is additionally vital. Fin density, fin height, and base thickness all influence the warmth sink's capability to dissipate heat. Computational Fluid Dynamics (CFD) simulations can be used to improve the look and forecast thermal effectiveness prior to physical prototypes are constructed. taking into consideration airflow and air flow throughout the enclosure can be significant, as suitable airflow boosts the warmth sink's effectiveness.

Value vs. Extruded Profiles Heatsink general performance: Balancing customized warmth Sink specs

While maximizing thermal functionality is often a primary purpose, cost is also a significant thought when creating custom made warmth sinks. greater-efficiency products like copper will improve the General Price compared to aluminum. in the same way, advanced geometries that require intricate machining or specialised production procedures will likely generate up charges. Choosing the appropriate producing process, for instance extrusion for Extruded Profiles Heatsink, can considerably influence Price tag-success. it is vital to thoroughly Consider the thermal demands of your respective application and identify locations exactly where effectiveness could be well balanced with Price personal savings. one example is, optimizing fin density or picking a far more cost-effective alloy can usually offer a very good stability concerning thermal efficiency and spending plan. Sourcing your customized warmth sinks from reputable manufacturers who offer you style and design help and price engineering can more help in attaining the optimum Price tag-performance ratio. Renxin Precision, by way of example, gives An array of custom made heat sink alternatives and can provide expert guidance on optimizing your style for the two general performance and cost.

In conclusion, custom made heat sinks are vital components for guaranteeing the trustworthiness and efficiency of electronic gadgets in a wide array of industries. By comprehension The main element design factors and thoroughly balancing Expense with overall performance, you may produce a tailor made thermal Resolution that fulfills the specific requires of your software. Never hesitate to examine the many benefits of Extruded Profiles Heatsink and seek the advice of with experienced companies like Renxin Precision to find the perfect Option to your thermal administration worries. get started optimizing your thermal efficiency right now!

Scott Baio Then & Now!

Scott Baio Then & Now! Michelle Pfeiffer Then & Now!

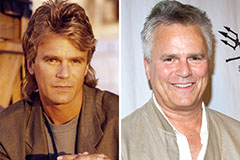

Michelle Pfeiffer Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!